We hate returns just as much as you do

Don’t waste your time and money with a company that can’t prove their results. We average 600-700 boosters a year and have rebuilt over 13,000 power brake boosters with less than a 1% rate for warranty work. Where else can you get nearly 100% done-right-the-first-time kind of craftsmanship? That’s because we are the ONLY company that uses the 4 Step Booster Quality InspectionTM to ensure that your booster is rebuilt properly THE FIRST TIME.

-“Booster” Dewey

The Booster Registry SystemTM & Our 4 Step Booster Quality InspectionTM

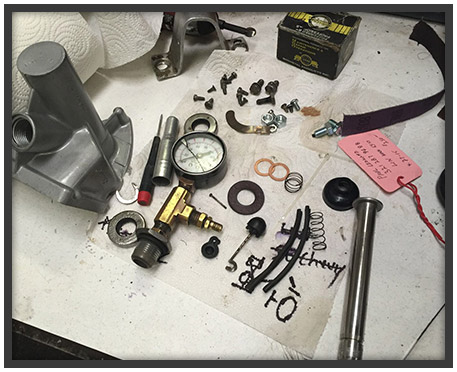

We offer a free service that sets us apart from any other rebuild company in the industry. We call it the Booster Registry SystemTM. Every booster that comes to our shop is tagged so that we can keep track of its history and the issues it may be having. This way, on the off chance that the booster has to have any warranty work on it, we can review our records and see what might be causing the problem. This also guarantees that when it’s time to rebuild the booster again, after it has gone through its typical life cycle of 6-9 years, we know what issues that particular booster has had in the past, if any.

After the booster has been entered into our Booster Registry SystemTM, we begin the rebuild process and our 4 Step Booster Quality InspectionTM. Unlike many other rebuild shops we don’t just test the booster when it is completed, we test it all along the assembly line so that if we encounter any problems we can address them immediately, saving both time and money.

Here’s a summary of how we test your booster to make sure you get the most miles out of it.

Inspection #1

After the entire power brake booster has been disassembled, cleaned, media blasted, and prepped for assembly, we test the master cylinder with compressed air to ensure a proper seal and pressure release.

Inspection #2

Next we check the vacuum pistons for leaks.

Inspection #3

Next we test the master cylinder to the prepared canister by inserting the vacuum piston inot the canister and adding back pressure into the master cylinder. This shows that the vacuum piston is working correctly.

Inspection #4

Finally, we assemble the entire power brake booster and test it all over again to make sure nothing has changed in the process of assembling the unit. Once it passes the final inspection then the power brake booster is packed and return shipped.

STOP! Don’t take a chance with your brakes!

With less than a 1% return rate no one rebuilds a booster like Ed Strain Inc. No body.